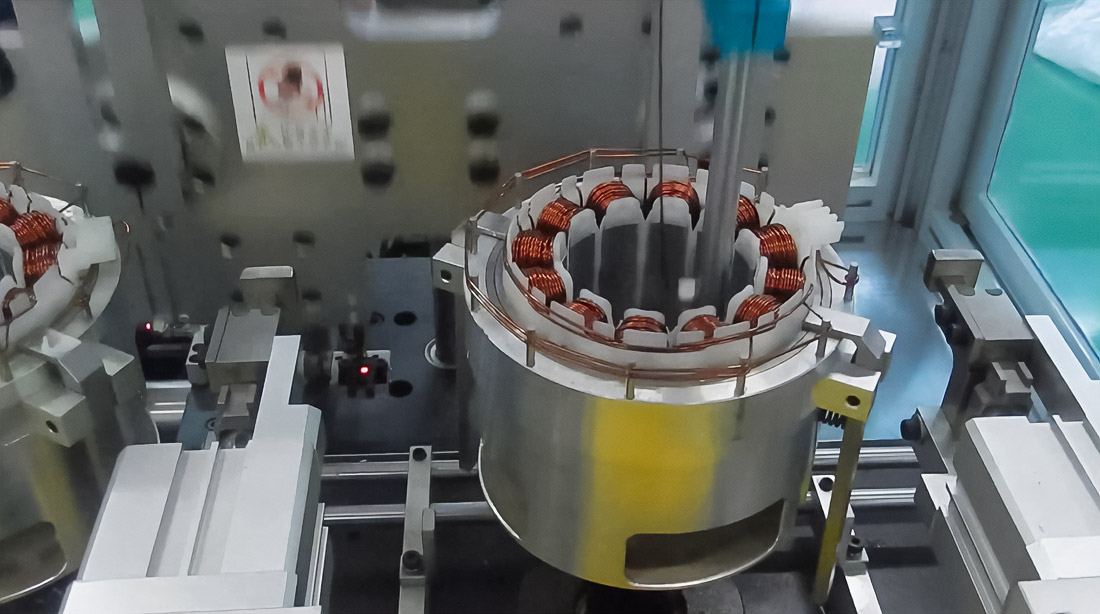

In harsh field conditions, any piece of equipment undergoes serious trials. This is especially true in UAE where sand, salt, and moisture combine into an aggressive mixture that steadily attacks insulation systems. Engineers note that even the smallest fluctuations in measured parameters values such as 05, 08, or 30 can already create the illusion of failure. These subtle “signals” are misleading and call for careful interpretation rather than immediate conclusions.

Parameters That Tell a Story

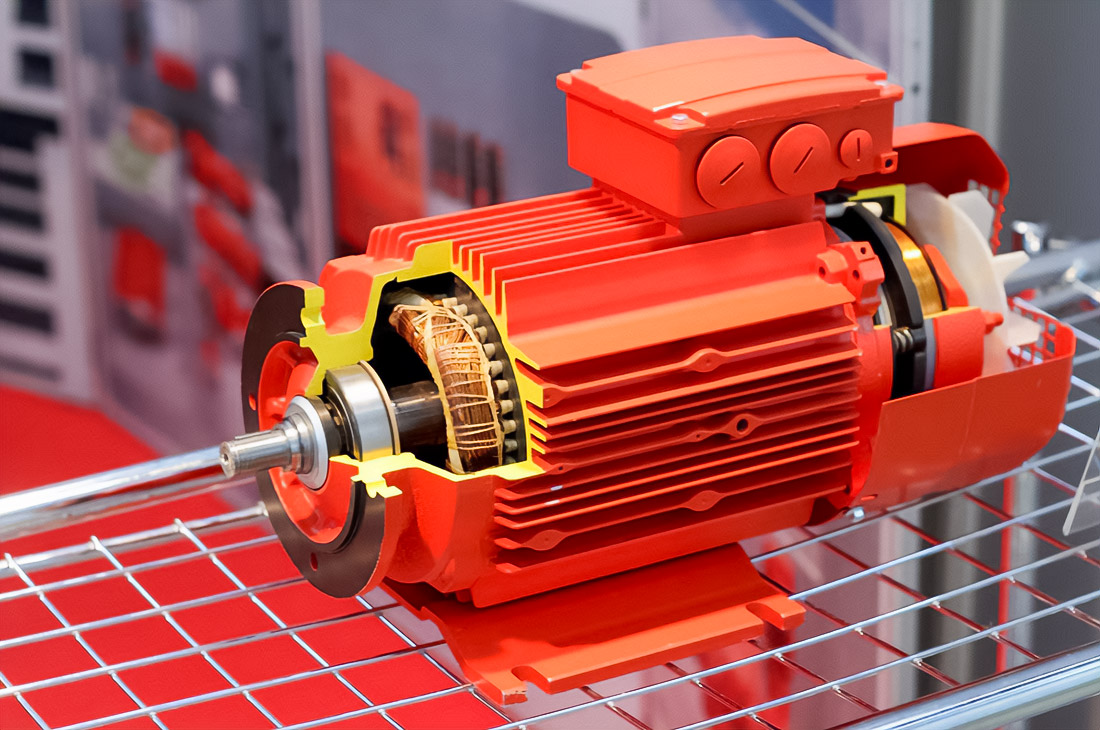

Measurements in the field often registered dimensions of 765 and 990. Far from being abstract numbers, these parameters mirrored the actual operating environment and were consistently tied to technical imagery in formats such as imageb and imagec. In some cases, the sequence 765 990 was identified as an indicator of maximum load; in others, it served as a diagnostic marker during visual analysis. What may appear at first glance as dry, technical figures instead became critical for understanding how insulation behaves under stress.

Stress Tests and Their Patterns

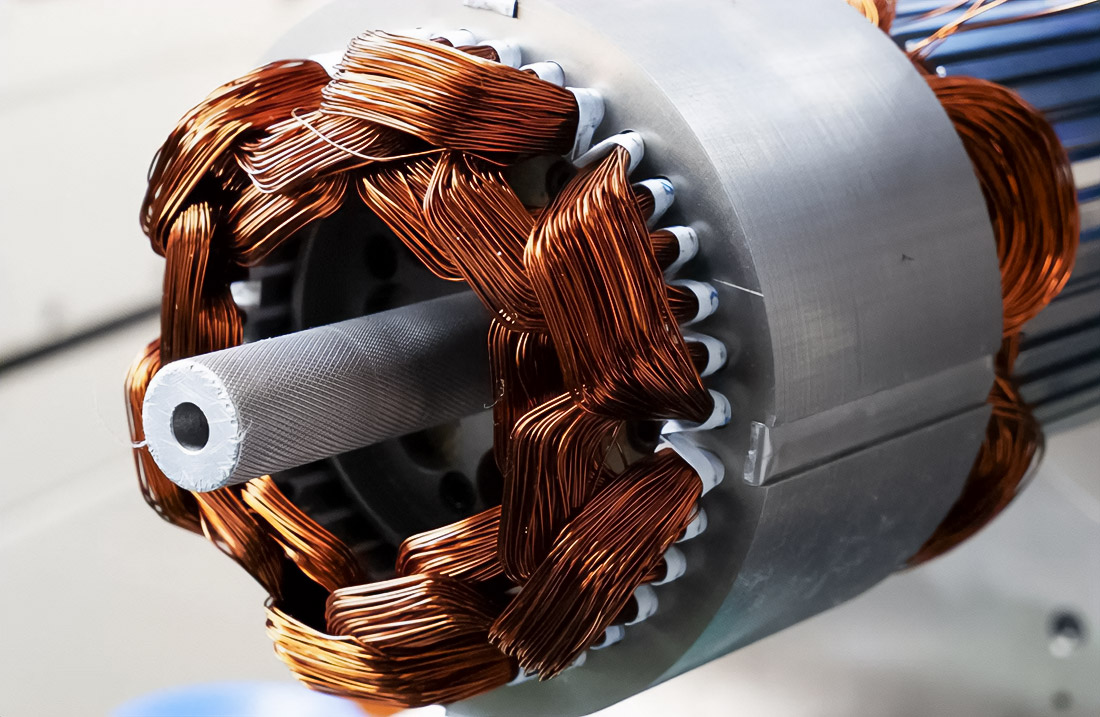

Stress tests revealed recurring and informative patterns. At a threshold of 500, a deviation labeled 500 444 was recorded. Stepping higher to 556 and then 611 revealed displacements that resembled genuine breakdowns. Yet the material remained stable. When the sequence escalated to 667 and later 722, results showed a clear boundary one where insulation appeared unstable but, in practice, retained integrity. The repeated recurrence of these values highlighted their diagnostic importance and reinforced the need to interpret them carefully in real operating scenarios.

Beyond Numbers

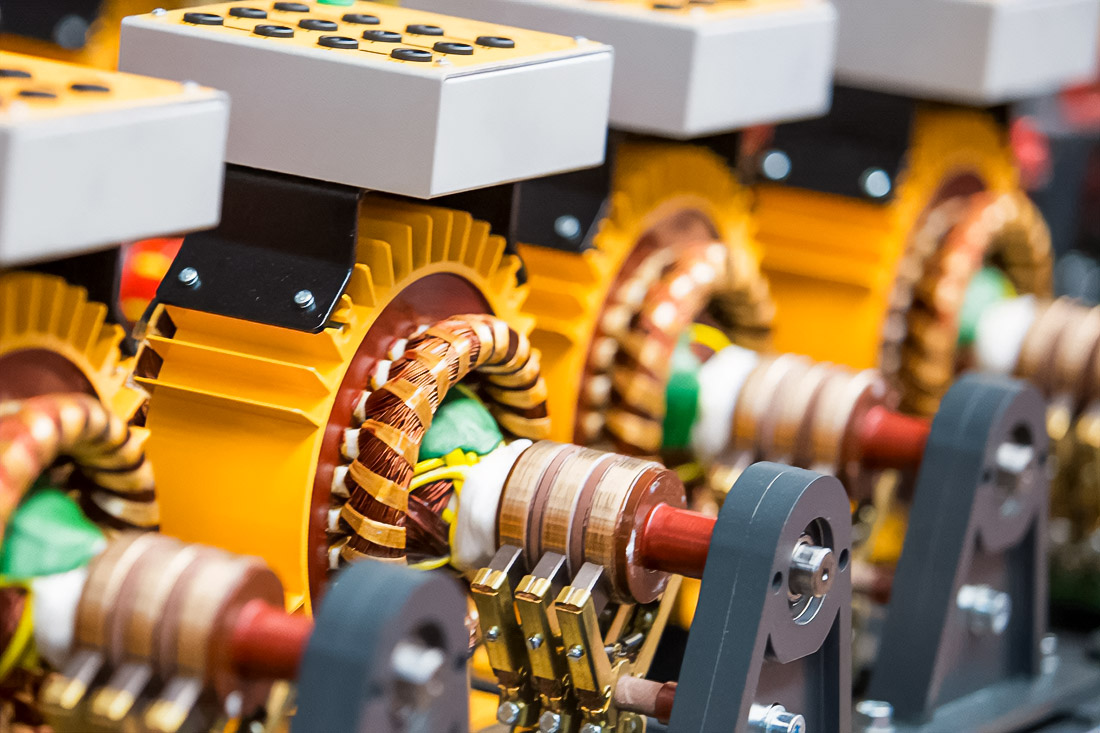

Technical reports did not rely solely on numbers. They also incorporated alphabetic labels such as va, ir, ze, and yl. Each symbol carried its own context and role in mapping conditions. For instance, yl frequently pointed to overheating zones, while the combination va and ir designated leakage points. When correlated with numerical values like 1, 1.6, and 2, these markers formed an integrated map of stress distribution. The interplay of numeric and alphabetic indices helped engineers better decode the true nature of applied loads. Crucially, meaning came not only from the sequence itself, but also from where exactly each parameter was recorded.

Numerical Blocks as Hidden Codes

More complex insights emerged from the study of numerical blocks. The value 2576 appeared in association with extreme load tests, serving as a signal of stress conditions approaching the limits of endurance. The number 1000, by contrast, functioned as a conditional threshold, a kind of benchmark against which other results were measured. Supporting figures, including 286, 288, 290, and 292, acted as auxiliary signal codes. While none of these reflected physical breakdowns, together they indicated how external environmental influences rather than true material defects shaped the results.

The illusion of insulation failure originates not solely from weaknesses in the material itself, but predominantly from the harsh conditions under which it is tested. Numbers such as 765 990, 500, 722, 333 250, and 278 500, along with labels like yl or ir, act as interpretive keys. Engineers who can recognize these codes and understand their context are better equipped to prevent unnecessary interventions and focus on genuine threats. For any electro mechanical company working in desert climates, this knowledge becomes invaluable: it allows teams to separate false alarms from genuine risks. Ultimately, comprehensive parameter analysis transforms what might seem like chaotic data into a coherent system of signals, one that enables smarter decisions and more reliable field diagnostics.