Why are non-standard radii necessary? MEP trails often run around columns, along ceilings, and walls, where space is limited and minimal bending radii are required. Using standard 90° angles is not always feasible — sometimes a flexible contour of 150 mm, 300 mm, 450 mm, or more is needed to navigate the space efficiently.

Too small a radius can cause bending of cables and loss of insulation integrity.

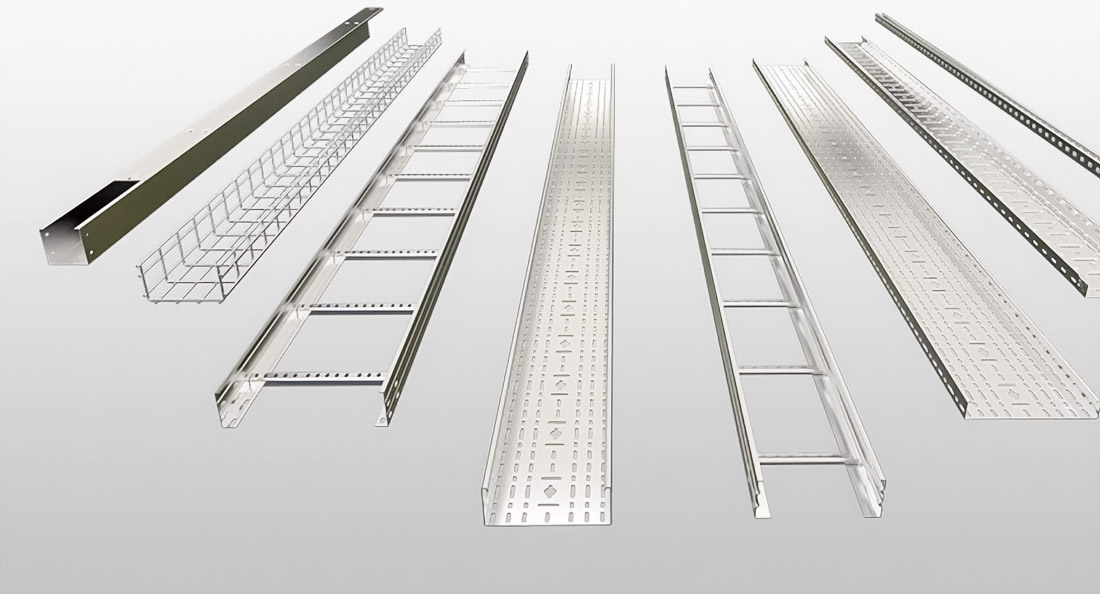

2. How do the cable tray adapt to the radii

Suppliers in Dubai offer ready-made fittings with radii of 150, 300, 450, 600 and 900 mm, which correspond to the actual catalogues of technical solutions used in the region.

Bends, tees, risers, and reducers are available, manufactured with a preset radius, making it easier to control cable paths through MEP designs.

3. Technical requirements and standards

Materials: Usually galvanized steel, stainless steel or aluminium trays are used.

Coating: hot-dip galvanizing (ISO 1461) for corrosion protection and long service life.

The accuracy of the dimensions and the internal radius is guaranteed so that the cables do not bend and are not subjected to mechanical stress.

4. Why is it important for engineers and contractors

- The probability of failures due to mechanical damage to the cable during installation is reduced.

- The installation quality and visual accuracy of the trails are improved.

- Installation time and the need for additional processing on site (cutting, welding, bending) are reduced.

5. Logistics and service

Local cable tray suppliers in Dubai usually stock radius fittings of standard sizes (150-900 mm).

Fast delivery and installation is possible without a long wait for the manufacture of a special element.

Summary

Complex MEP routes often require cable trays with a non‑standard radius of 150-900 mm.

Along with traditional straight sections, suppliers provide special fittings (bends, tees, reducers) with the required radius.

This approach provides:

– smooth cable routing without kinks.

– Reducing the risk of damage.

– operational installation at the facilities.

Complex MEP cable runs require careful planning and high engineering standards to ensure safety and efficiency. Meeting these challenges demands precise design and quality components. This confirms that cable tray suppliers in Dubai are ready to provide solutions that comply with stringent engineering requirements.